Titanium Bearing Pellets

Titanium Bearing Pellets Specification

- Rating

- High purity industrial grade

- Feature

- High melting point, corrosion resistance, homogeneous structure

- Condition

- New

- Type

- Solid Pellets

- Usage

- Industrial, Metallurgical, Laboratory, Catalysis

- Size

- Custom and standard sizes available

- Dimensions

- Diameter range: 1 mm to 10 mm, Length: up to 20 mm

- Weight

- Variable; typically packaged from 1 kg to 50 kg

- Application

- Steel production, Alloy manufacturing, Vacuum deposition, Research

- Capacity

- Packaged as per requirement; bulk and small quantities

Titanium Bearing Pellets Trade Information

- Minimum Order Quantity

- 1000 tons Tons

- FOB Port

- Any Chinese seaport

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD)

- Supply Ability

- 200000 Tons Per Year

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- No Packing in bulk

- Main Export Market(s)

- Middle East, Eastern Europe, Australia, Africa, North America, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Titanium Bearing Pellets

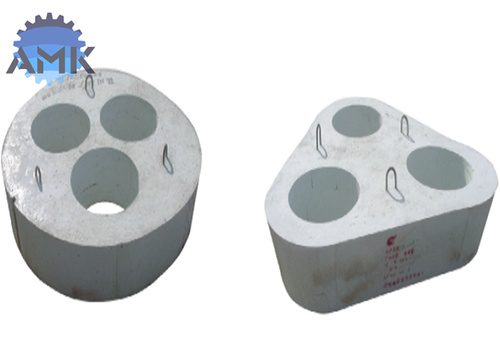

Titanium Bearing Pellets

Titanium Bearing Pellets For Blast Furnace

Chinese people firstly found Titanium could be used as protection to the blast furnaces on 1980 in Chinese state-owned LIUZHOU IRON AND STEEL GROUP and firstly started to produce the titanium bearing pellets on 1999.

- Size: 42x42x29mm

- TiO2: Min.25%

- Fe: Min.25%

- Ti O2& Fe: Min.50%

- SiO2: Max. 17%

- Tumbler Index(+6.3mm): Min.75

- Compressive strength(N): Min.3000

Application:

- As protection in the blast furnaces and improve the lifetime of blastfurnaces.

- Our annual output: 100,000 Tons.

- Sales: Domestic big steel plants and Japan, Malaysia, Turkey etc.

Advantages of the material:

1. Fewer consumption, only 30-40KG titanium bearing pellets needed for 1 ton pig iron

2. Fewer slag materials involved, the coke consumption reduced, narrow cohesive zone, increasing the pig iron yield and reduced the cost eventually.

3. The size is rather regular and the quality is stable, good smelting performance, high compressive strength and tumbler index, improving the breath ability of the blast furnace.

4. Improve the steel production and increase the strength of the pig iron (10-20Mpa could be increased).

Exceptional Material Purity and Quality

Our titanium bearing pellets achieve purity levels of 99.5% to 99.99% Ti, with typical impurities limited to oxygen, carbon, iron, and nitrogen at only parts per million. This high purity ensures superior performance and minimal contamination in sensitive or critical applications, including laboratories, catalyst research, and precision metalworking.

Versatility Across Industries

With their high melting point and superior corrosion resistance, these pellets are suitable for a range of demanding uses, from steel production and alloy creation to advanced vacuum deposition techniques. Their homogeneous structure provides excellent mechanical and chemical consistency, making them the go-to choice for industries requiring stringent material standards.

Secure Packaging and Custom Sizing

We supply our titanium pellets in sealed, protective containers, packed under vacuum or inert argon to maintain integrity during storage and transit. Both bulk and small quantities are available, with custom sizing options ensuring precise fit for your projects. Orders can be tailored to specific requirements, with lead times of 2-4 weeks for bulk shipments.

FAQs of Titanium Bearing Pellets:

Q: How are titanium bearing pellets packaged for optimal purity?

A: Titanium bearing pellets are sealed in vacuum or argon-filled containers, effectively protecting them from moisture and contamination. This method ensures their high purity is maintained during storage and shipping.Q: What applications benefit most from these high-purity titanium pellets?

A: These pellets are ideally suited for industrial processes such as steel production, alloy manufacturing, laboratory research, vacuum deposition, and catalytic activities, where high temperature stability and purity are critical.Q: When can I expect delivery for bulk orders of titanium pellets?

A: Lead time for bulk orders typically ranges from 2 to 4 weeks, depending on the quantity and any custom size requirements specified at the time of order.Q: Where should titanium bearing pellets be stored for best results?

A: To preserve quality and prevent oxidation or contamination, store the pellets in a dry, protected environment inside their original sealed containers until use.Q: What is the process for customizing pellet size and quantity?

A: You can specify both standard and custom dimensions (diameter: 1 mm to 10 mm, length up to 20 mm) and quantities when placing your order, ensuring a perfect fit for your application needs.Q: How does the high purity of these pellets benefit industrial usage?

A: The exceptional purity minimizes introduction of unwanted elements into your process, enhancing the performance and quality of finished alloys, coatings, or research outputs.Q: What certifications ensure the reliability of these titanium pellets?

A: Our pellets are RoHS and ISO certified, verifying they meet rigorous international safety, quality, and environmental standards demanded in advanced industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Making Furnaces Category

Eaf Lid

Price 3000 USD ($) / Box

Minimum Order Quantity : 2 Pieces

Usage : Other, Steel Melting/EAF Cover

Condition : New

Dimensions : Tailored to furnace diameter (as specified)

Feature : Heat resistant, Durable, High strength

Graphite Electrode Holder

Price 5000 USD ($)

Minimum Order Quantity : 2 Pieces

Usage : Other, Industrial, Foundry, Steel Plants

Condition : New

Dimensions : As per drawing/specification

Feature : Durable, Corrosion Resistance, Precision Engineered

Ladle Heater Burner

Price 5000 USD ($)

Minimum Order Quantity : 5 Pieces

Usage : Other, Ladle Preheating

Condition : New

Dimensions : As per model / requirement

Feature : High Efficiency, Uniform Heating, Robust Design, Energy Saving

Water Cooled Lid

Price 30000 USD ($)

Minimum Order Quantity : 1 Set

Usage : Other, Industrial Furnace Application

Condition : New

Dimensions : Standard and as per custom design

Feature : Efficient Cooling, Longer Service Life, Corrosion Resistant, Leak Proof