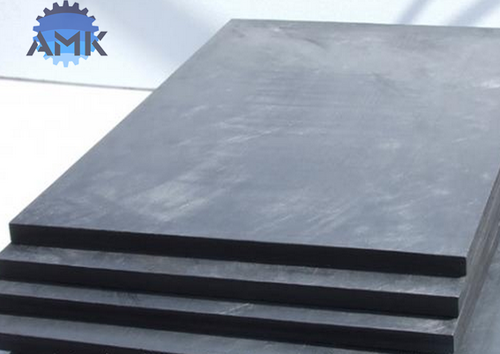

Reinforced Graphite Sheet

Reinforced Graphite Sheet Specification

- Surface Treatment

- Reinforced with tanged, flat, or wire mesh (commonly stainless steel, tin plate, or nickel)

- Features

- Explosion bonded reinforcement, resistance to chemicals and thermal cycles, asbestosis free, fire safe

- Operating Temperature

- -200C to +550C (depending on specific reinforcement and application)

- Used For

- Flange sealing, pipe and vessel gaskets, engine gaskets

- Pressure Ratings

- Up to 140 bar (varies with sheet thickness and reinforcement type)

- Automation Grade

- Manual

- Material

- Reinforced Graphite

- Style

- Sheet

- Properties

- High compressibility and recovery, excellent chemical resistance, non-oxidizing and non-corrosive

- Condition

- New

- Application

- Gasketing, sealing, high-temperature and high-pressure environments

Reinforced Graphite Sheet Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- Shanghai

- Supply Ability

- 30000 Pieces Per Year

- Delivery Time

- 25 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden case

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Reinforced Graphite Sheet

Reinforced Graphite Sheet

Type:

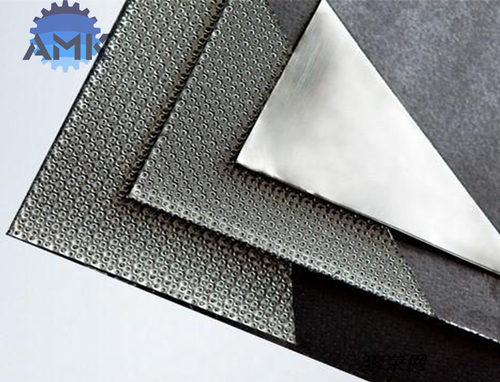

Reinforced graphite sheet with smooth metal, reinforced graphite sheet with metal mesh, reinforced graphite sheet with tanged metal

Characteristics:

The reinforced graphite sheet is made from high-carbon flexible graphite and flator tanged metal material. The metal material includes SS316, SS304, carbon steel, Tin-plating, Zn-plating etc. It possesses excellent characteristics as good compressibility and recovery etc.It can be used under high-temperature and high-pressure transfer of steam,water, gases, chemicals and corrosives.

Usages:

The reinforced graphite sheet is mainly used to make gasket and compressors for cylinders and internal combustion engines, or other different kinds of gasket for tube and flange.

Exceptional Performance in Extreme Conditions

Reinforced Graphite Sheets are designed to withstand severe thermal and pressure environments. Their explosion-bonded metal reinforcement offers high mechanical strength, while retaining the chemical inertness and flexibility of graphite. This makes them ideal for handling aggressive media in industries such as refineries, petrochemicals, and power generation.

Versatile Sizes and Customization

Available in standard sheets of 1000 mm x 1000 mm and 1500 mm x 1500 mm, and offering thickness options from 0.5 mm to 3 mm, these graphite sheets can be custom cut to exact specifications. This flexibility ensures precise fitment for various flange, pipe, and engine gasket requirements, meeting the unique needs of each application.

Reliability and Standards Compliance

Our sheets are rigorously manufactured to comply with international standards such as ASTM F36, DIN 52900, and BS 7531. Low chloride and sulphur content ensure compatibility with sensitive equipment, while being asbestosis free and fire safe supports user safety and environmental compliance.

FAQs of Reinforced Graphite Sheet:

Q: How is reinforced graphite sheet used in gasketing applications?

A: Reinforced graphite sheet is commonly cut into gaskets for sealing flanges, pipes, vessels, and engine components. Its compressibility and recovery properties make it ideal for environments requiring reliable sealing under fluctuating temperatures and pressures.Q: What reinforcement types are available for these graphite sheets?

A: These sheets are reinforced with either tanged stainless steel (SS 316 or SS 304), flat stainless steel, or wire mesh, which provide additional mechanical strength and facilitate handling, installation, and durability in demanding industrial uses.Q: When should I choose reinforced graphite over non-reinforced sheets?

A: Reinforced graphite sheets are preferred when higher mechanical strength, improved recovery, and enhanced resistance to blowout are critical, such as in high-pressure, high-temperature, or cycling environments.Q: Where can reinforced graphite sheets be applied?

A: They are suitable for a wide range of industries, including oil and gas, chemical processing, power generation, and automotive, specifically for flange sealing, pipe and vessel gaskets, and engine gasket applications.Q: What is the process for customizing sheet sizes or thicknesses?

A: Custom sizes and thicknesses can be specified at the time of order. The manufacturer will cut or manufacture the sheets to your exact requirements, ensuring compatibility with your specific sealing or gasketing application.Q: What are the main benefits of using reinforced graphite sheets?

A: Key benefits include excellent chemical resistance, high compressibility and recovery, durability under thermal cycles, and fire safety. The metal reinforcement provides structural support, making these sheets reliable for demanding application conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Products Category

Graphite Ring

Price 50 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Sealing in valves, pumps, chemical and petrochemical industries

Used For : Used for static and dynamic sealing applications

Material : Pure Graphite

Properties : High thermal conductivity, Chemical resistance, Low friction, High compressibility

Graphite Container

Price 5000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial Furnace, Laboratory Use, Metal Melting

Used For : Holding and Melting Metals, HighTemperature Applications

Material : High Purity Graphite

Properties : High Thermal Resistance, Chemical Inertness

Graphite Stopper

Price 100 USD ($)

Minimum Order Quantity : 10 Pieces

Application : Industrial crucibles, Foundries, Metallurgical processes

Used For : Controlling flow of molten metal in crucibles

Material : High Purity Graphite

Properties : Excellent thermal conductivity, Good chemical resistance, High mechanical strength

Carbon And Graphite Felt

Price 1000 USD ($)

Minimum Order Quantity : 2 Pieces

Application : Thermal insulation, vacuum furnaces, hightemperature filtration

Used For : Heat insulation, energy storage systems

Material : Carbon and Graphite Felt

Properties : High temperature resistance, chemical stability, lightweight