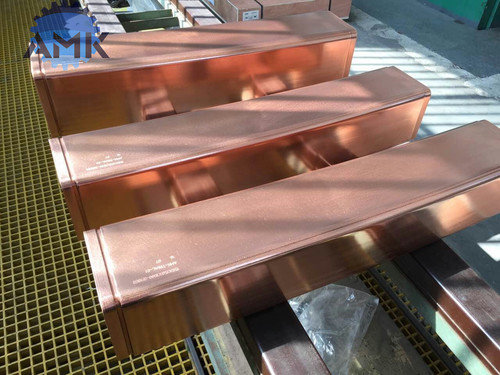

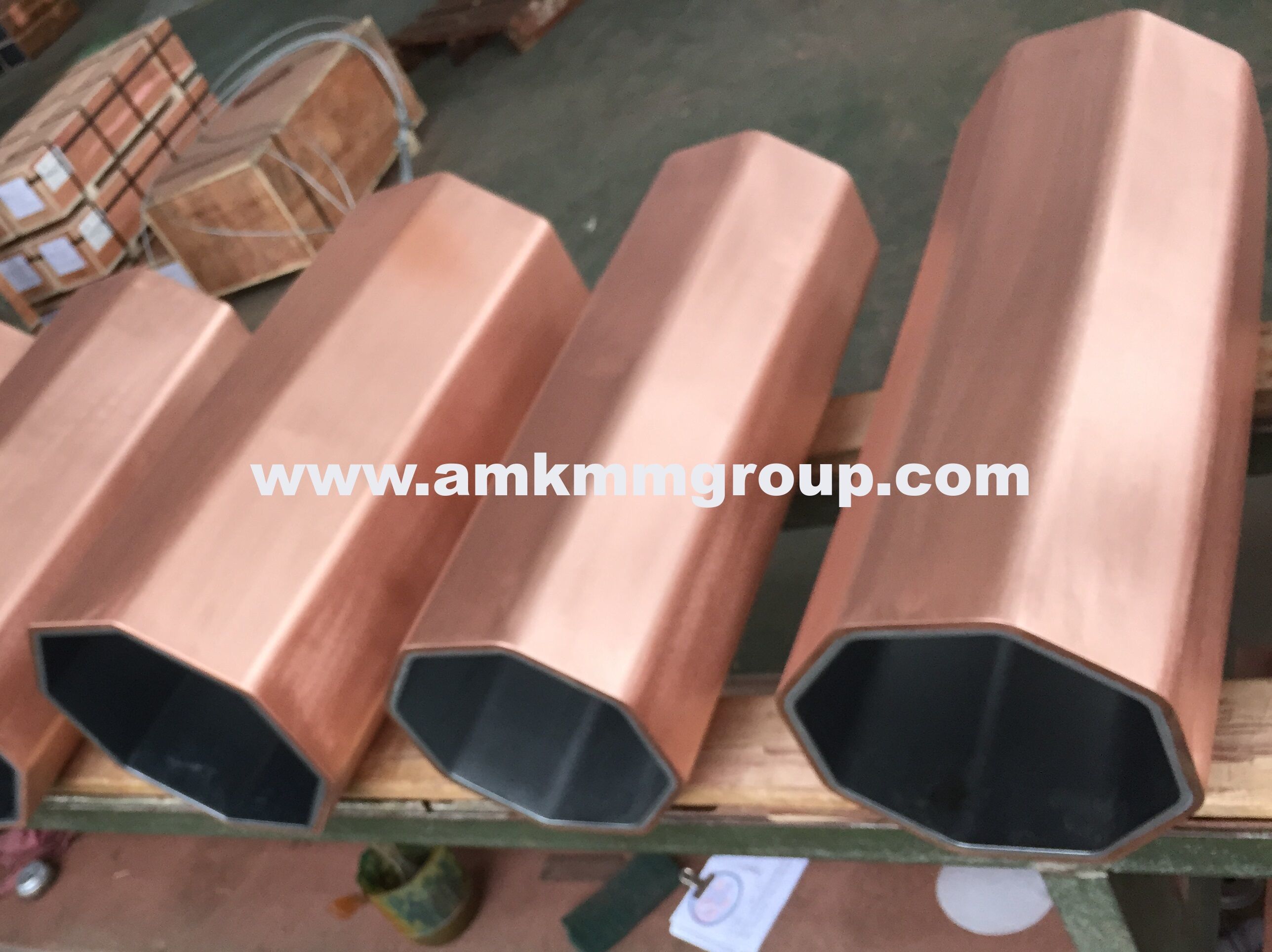

Copper Mould Tube

Copper Mould Tube Specification

- Material

- Copper

- Surface Finishing

- Polishing

- Weight

- as per drawing Kilograms (kg)

- Color

- copper

Copper Mould Tube Trade Information

- Minimum Order Quantity

- 120 Kilograms

- FOB Port

- Shanghai

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T)

- Supply Ability

- 300000 Kilograms Per Year

- Delivery Time

- 30-40 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden cases

- Main Export Market(s)

- South America, Western Europe, Eastern Europe, Africa, Middle East, Asia

- Main Domestic Market

- All India

About Copper Mould Tube

Copper Mould Tube For CCM

Copper mould tubes are used as a cooling spare part for continuous casting machines.

- Square copper mould tube

- Rectangular copper mould tube

- Round copper mould tube

- Beam blank copper mould tube

- Non-standard copper mould tube

-

Square Mould

- 50X50650X650

- Rectangular (100500)X650

- Round mould 110- 1500

- Design with double taper, triple taper

- Multi-taper, parabolic taper and various kinds of continuous taper

- Non-standard mould

- Beam blank mould

The materials of copper mould tubes should be the ones with good tensile strength, fatigue strength, proper hardness, low elongation and high heat conductivity coefficient. As a result, material like phosphorous de-oxidize copper DHP,CUAG CR-ZR-CU are widely accepted by users of all countries.

Coatings:

Copper has lower hardness which leads to lower anti-abrasive property. Therefore, the area at the lower part of the moulds, where the stress increases drastically due to shells, will be more severely worn. To increase the life time of copper moulds, Uniform mould interior surface plating with suitable hardness is needed. We use hard chrome plating to increase the life of mould tubes. The plating thickness will be controlled in the best range. As for the coating of copper mould plates, based on our years of experience, we are able to provide Cr coating, Ni-Cr coating, Ni-Fe coating and Ni-Co-Cr coating to meet the demand of various customers both at home and abroad.

Notice:

1. Please use the copper mould tubes within one year.

3. Keep the copper mould tubes away from acidic materials, especially the internal coating surface.

4. Polish the external surface of the copper mould tubes with sand paper if oxidized.

5. Pouring the molten steel to the center of the copper mould tubes

6. Avoid internal surface scratch of the moulds caused by manual operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Equipment Category

Torch Cutting Machines

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Other Ductile Iron, Mild Steel

Surface Finishing : Polished

Product Type : Other, Torch Cutting Machine

Color : Blue & Yellow

Mould Assembly

Price 20000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Painting

Product Type : Cast Equipment

Water Jacket

Price 10000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Polishing

Product Type : Cast Equipment

Continuous Casting Spare Parts

Price 10000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Surface Finishing : Painted

Product Type : Other

Color : Gray